What is ToF?

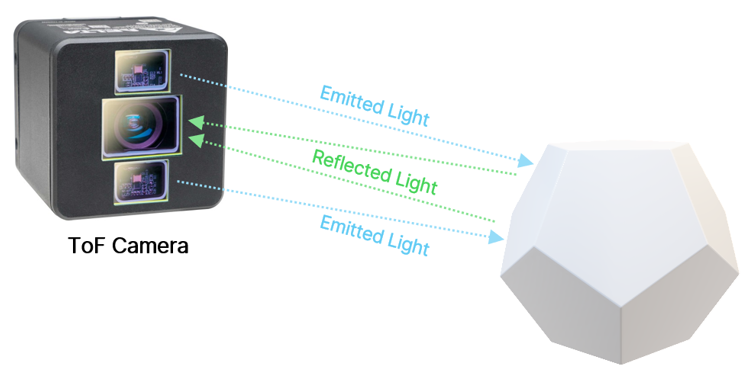

ToF (Time of Flight) is a technology that measures distance by emitting light and capturing the reflected light from an object. A ToF camera emits infrared light and calculates the distance between the object and the camera by measuring either the time it takes for the light to travel to the object and back, or the phase shift of the light wave. This technology is especially well-suited for applications that require real-time depth data, such as object volume measurement, pallet detection, and robot obstacle avoidance and navigation.

How does a ToF camera work?

1. Emit Light Pulses / Modulated Light Source

The built-in light source (infrared laser or LED) emits light signals toward the target object.

2. Reflected Light Collection

The emitted light reflects off the surface of the object and is collected by the camera’s lens.

3. Sensor Captures Time Delay / Phase Shift

The image sensor detects the returning light signal and records the time delay or phase shift relative to the emitted signal.

4. Distance Calculation by Processing Unit

Based on the recorded data, the processing unit calculates the distance of each pixel and generates a corresponding 3D depth map.

What are the two types of ToF?

What are the two types of ToF?

Based on the underlying distance measurement principles and technology, ToF can be classified into two main types:

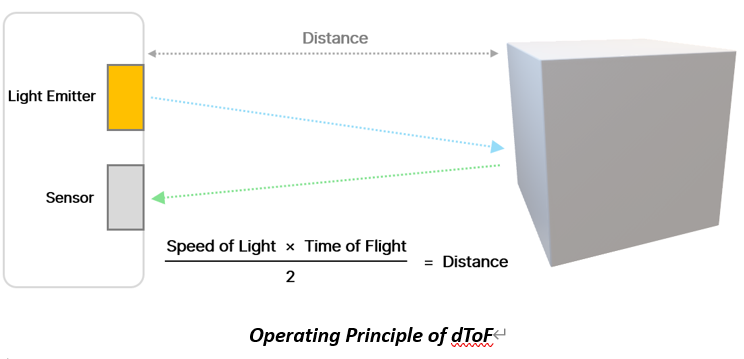

dToF (Direct ToF – Pulse-Based Measurement)

dToF is a distance measurement technology that uses short light pulses. The principle involves emitting a burst of infrared light in an extremely short time. When the light hits the surface of an object and reflects, the sensor records the time it takes for the light to travel to the object and return. The distance is then calculated based on the speed of light and the measured time delay.

Unlike iToF, which estimates distance by interpreting phase shifts, dToF directly measures the time light takes to travel. This eliminates ambiguity at long ranges, making it ideal for longer-distance measurements. However, measuring time differences in the nanosecond scale requires extremely high time resolution from the sensor and a more complex system design. As a result, dToF systems typically require dedicated high-speed timing circuits and are relatively more expensive.

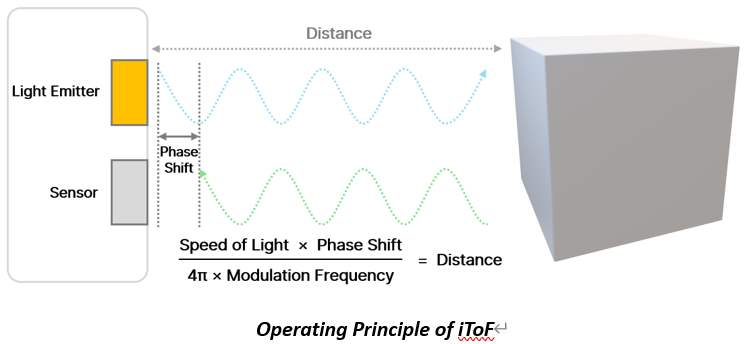

iToF (Indirect ToF – Continuous Wave Modulation Measurement)

iToF (Indirect ToF – Continuous Wave Modulation Measurement)

iToF measures distance by continuously modulating a light source. It works by varying the frequency or phase of infrared light over time, emitting a signal whose brightness changes rapidly. When this light reflects off an object and returns to the sensor, the system detects the phase difference between the emitted and received light waves and calculates the distance based on this phase shift.

Compared to dToF, iToF does not require generating ultra-short light pulses, which simplifies the system architecture and makes it easier and more cost-effective to implement. However, because iToF relies on a phase difference, it has a maximum unambiguous measurement range. If the measured distance exceeds this range, the results may repeat cyclically, causing ambiguity. Therefore, iToF is best suited for short- to mid-range applications, typically within 10 meters.

How is ToF technology applied?

How is ToF technology applied?

ToF cameras provide real-time, accurate 3D depth information and are commonly used in the following applications:

• Object Measurement and Positioning

Quickly obtains the 3D dimensions and position of objects for automated inspection and packaging.

• Pallet Positioning, Dimension Measurement, and Stacking Detection

Enhances warehouse and logistics space utilization while reducing transportation costs.

Learn more

• AGV / AMR Navigation and Obstacle Avoidance

Assists automated guided vehicles in detecting obstacles and the environment to achieve safe autonomous movement.

Learn more

• Robot Vision Perception and Arm Grasping Positioning

By fusing ToF and RGB images, the robot’s ability to recognize package color, shape, and size is enhanced, enabling precise execution of grasping and handling tasks.

Learn more

Delta ToF Solution