Tips for Choosing Industrial Cameras: Global Shutter vs. Rolling Shutter

About Shutters

A camera’s shutter controls the exposure time of an image sensor, influencing both image clarity and stability. Most industrial cameras today use electronic shutters, which can be categorized into “global shutters” and “rolling shutters”. These two types operate on different principles and are suitable for different application scenarios.

Operating Principles of “Global Shutter” and “Rolling Shutter”

What is a “Global Shutter”?

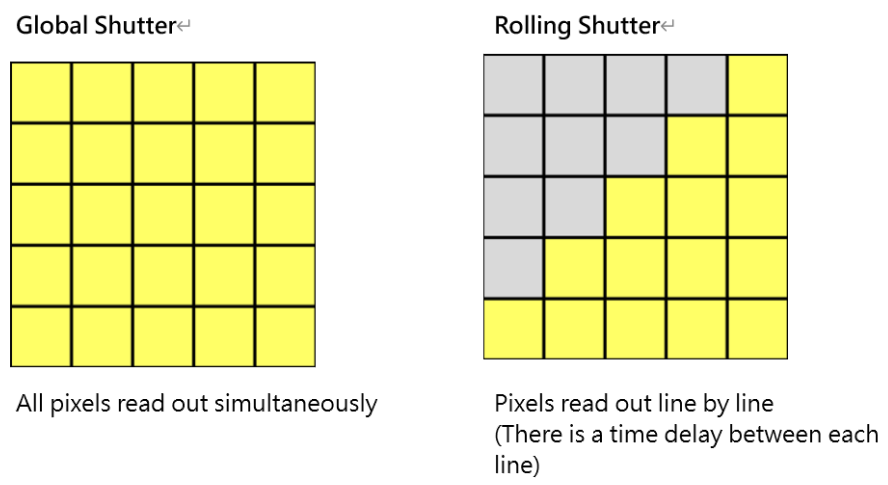

The image sensor in a global shutter exposes the entire frame simultaneously. All pixels collect light and stop exposure at the same time, ensuring that every pixel in the image corresponds to the exact same moment. Although pixel data is still read out line by line after exposure, this does not affect the temporal synchronization of the image. As a result, global shutters effectively prevent image distortions caused by timing differences, such as Skew or the Jello Effect. This makes global shutters ideal for capturing fast-moving objects, and delivering clear, stable, and distortion-free images.

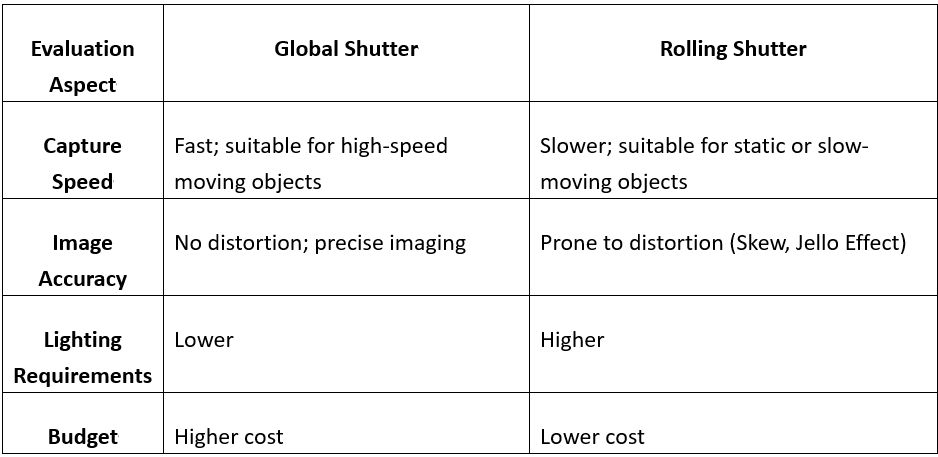

However, compared to rolling shutters, global shutter sensors are more expensive. Additionally, for the same sensor size, their low-light performance (sensitivity) may be slightly lower, requiring more abundant lighting to achieve the best results.

What is a “Rolling Shutter”?

The rolling shutter image sensor does not expose all pixels at once. Instead, exposure and data readouts are initiated sequentially, line by line—usually from the top to the bottom of the sensor. Although each row has the same exposure duration, the exposure start time for each row is slightly delayed.

This design simplifies circuitry and component requirements, resulting in lower manufacturing costs. Rolling shutter sensors also typically offer higher pixel densities and better low-light performance. For static or slow-moving subjects, rolling shutters deliver high image quality and cost efficiency.

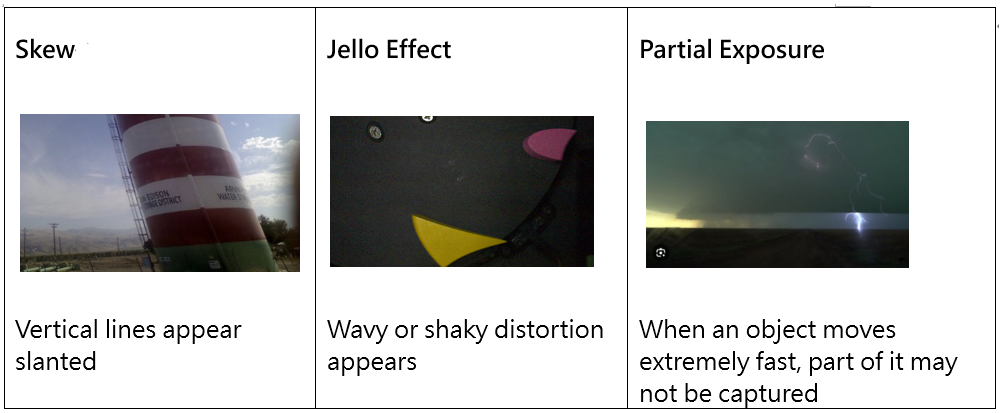

However, due to varying exposure times, rolling shutters tend to deliver image distortions when capturing fast-moving objects, such as skewed vertical lines, overall image warping (known as the Jello Effect), or even partial disappearance of objects (Partial Exposure). These issues can affect image interpretation and measurement accuracy.

Industrial Camera Selection Tips: Global Shutter vs. Rolling Shutter

Choosing the right shutter type depends on factors such as capture speed, image accuracy, lighting requirements, and budget considerations for your application. Below are some practical selection tips:

Based on Capture Speed:

▪️ High-Speed Moving Objects

• Pick-and-place: robotic picking, flexible feeding, parts assembly

• Inspection: conveyor packaging inspection, high-speed six-sided inspection of parts on production lines, insertion machines

Choose global shutters to avoid image distortion and improve recognition and measurement accuracy.

▪️ Static objects

• Stop-motion inspection, including label inspection and presence/absence inspection

Choose rolling shutters for their practical and economic advantages, which often offer a lower price for the same pixel resolution.

Based on Image Accuracy:

▪️ When high geometric accuracy is required (e.g., dimension measurement, geometric analysis, pick-and-place positioning):

Choose global shutters to ensure distortion-free images and improve algorithm reliability.

▪️ When slight image distortion is acceptable (e.g., presence/absence detection, screw type identification):

Choose rolling shutters to save budget without sacrificing quality.

Based on Budget Considerations:

▪️ Cost-Sensitive Applications:

Choose rolling shutter cameras for their competitive pricing and suitability for most static imaging and general inspection scenarios.

▪️ Performance-Oriented Applications:

Choose global shutters for improved image reliability and resulting stability when accuracy and speed are top priorities. Although slightly more expensive, they offer better long-term benefits.

In summary, the key factors in choosing between global shutters and rolling shutters are object movement speed and tolerance for image distortion.

▪️ If the subject moves at high speed or you have strict requirements for image quality, choose a global shutter without hesitation.

▪️ If the object is static and image distortion is not a critical concern, rolling shutter is a more economical and effective choice.

When making the final decision, we recommend that you consult with professional machine vision suppliers. They can provide expert advice and testing based on your specific needs.

Delta Industrial Cameras Offer Both Global Shutter & Rolling Shutter Options: