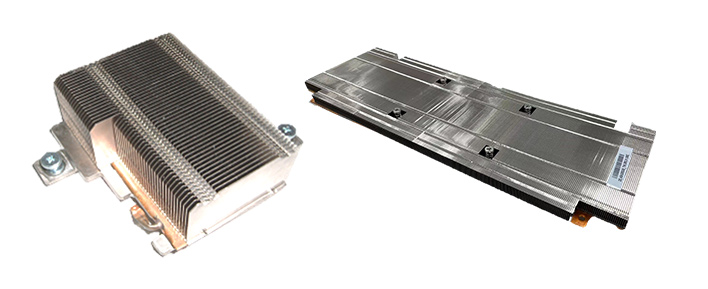

2D vapor chamber solution designed to handle high heat flux cooling applications

Delta has bonded heatsink on vapor chamber (VC) as advanced thermal management solution to address high heat flux cooling application. Compared to single-dimension heat conduction of heat pipe with lower limitation for supportable heat flux due to dry-out phenomenon, VC and its hollow vessel structure has advantage at heat spreading on planar direction by acting as a high heat flux transformer transforming heat source to wider but lower heat flux that can be removed by natural or forced convection conducted above heatsink. Delta possesses extensive engineering expertise and an in-house, highly automated process that has allowed us to deliver millions of vapor chamber modules to the market.

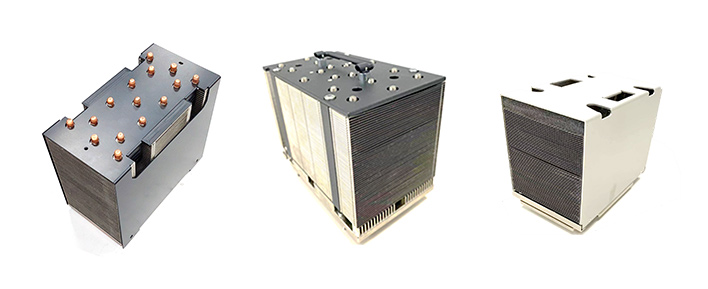

High-end 3D vapor chamber solution customized for high-power-density applications, eliminating the risk of water leakage

To address cooling for high power density without water leakage concern, Delta has developed high end 3D-VC solution, which both integrates the planar heat spreading benefits of VC and achieves upward heat conduction via inserting/ bonding heat pipes vertically on VC plate that eventually fulfills 3-dimensional heat transfer for cooling enhancement with traditional but reliable air. Delta views 3D VC as the essential key when it comes to defining the alteration between air & liquid cooling. Leveraging our expertise in both heat pipes and vapor chambers, we excel in combining these technologies to offer customers a high-performance and reliable choice.