Welding Solutions

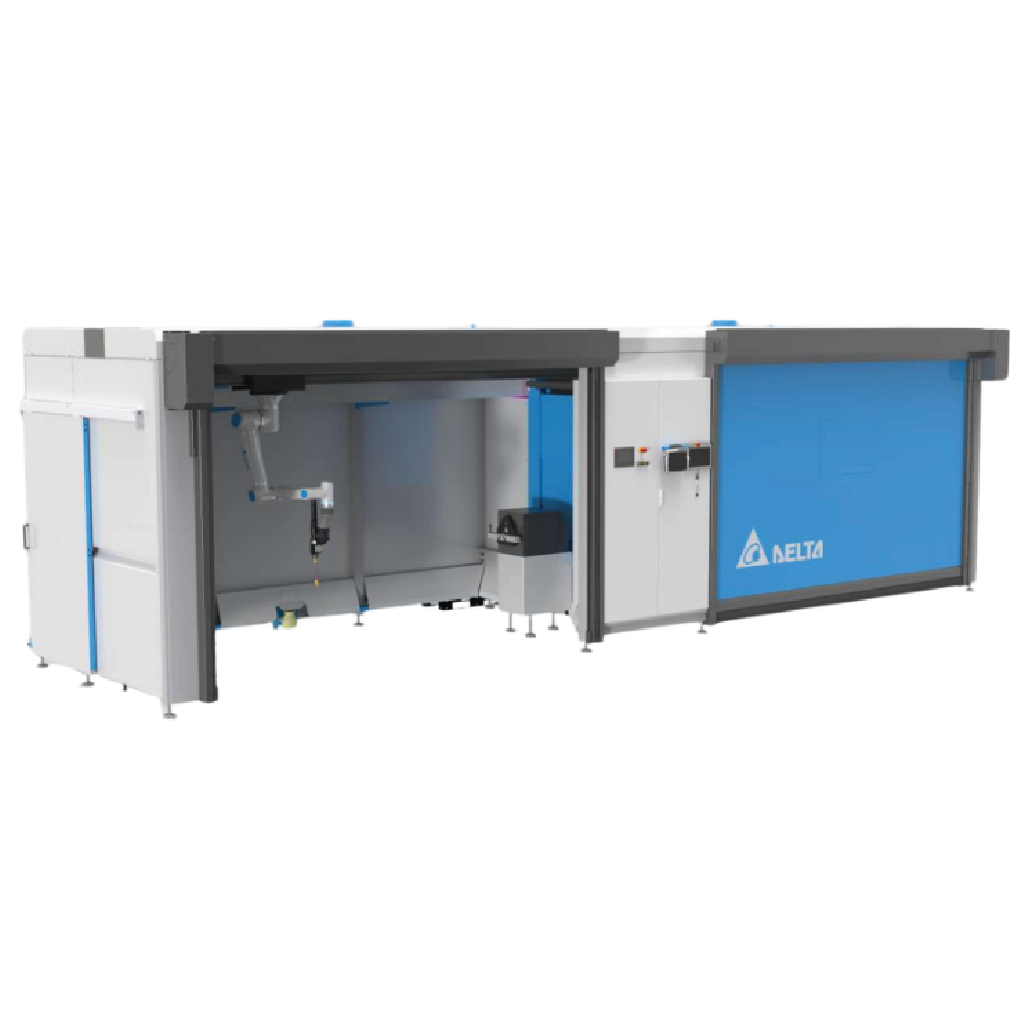

Smart Cells is an innovative concept that provides straightforward solutions for a wide range of applications. The toolkit portfolio offers a versatile toolbox that allows selection of exactly the components required for the specific application. During the entire concept phase through to series production, experienced specialists provide guidance and support.

Usage of standard components

Usage of standard components

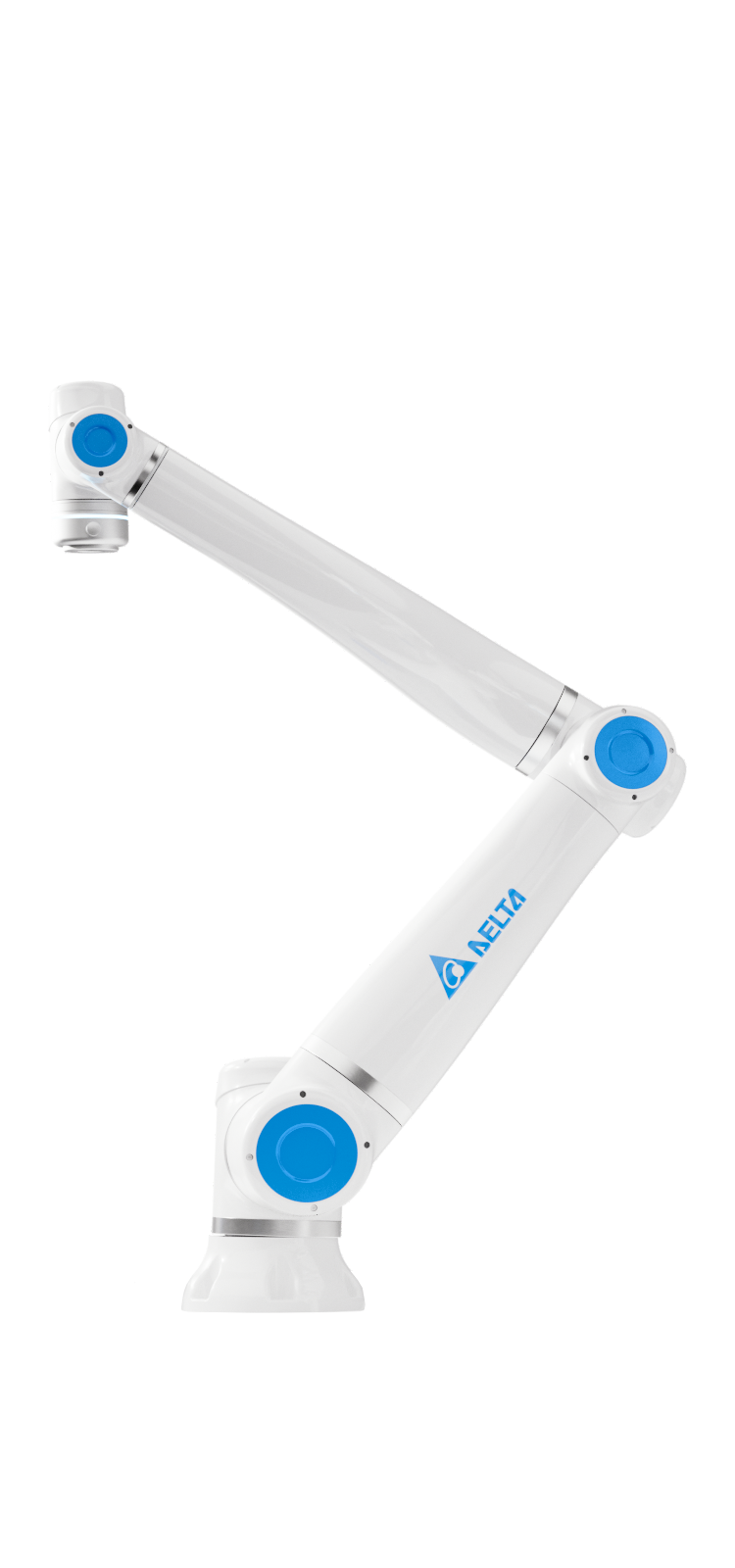

Can be used without any programming knowledge

Can be used without any programming knowledge

Perfectly tailored to customer needs

Perfectly tailored to customer needs

Proprietary handle and software guide for easy usage

Proprietary handle and software guide for easy usage

- Job-shop & contract fabrication

- SME machine builders & metalworking shops

- Agricultural & construction equipment

- Commercial vehicle & trailer makers

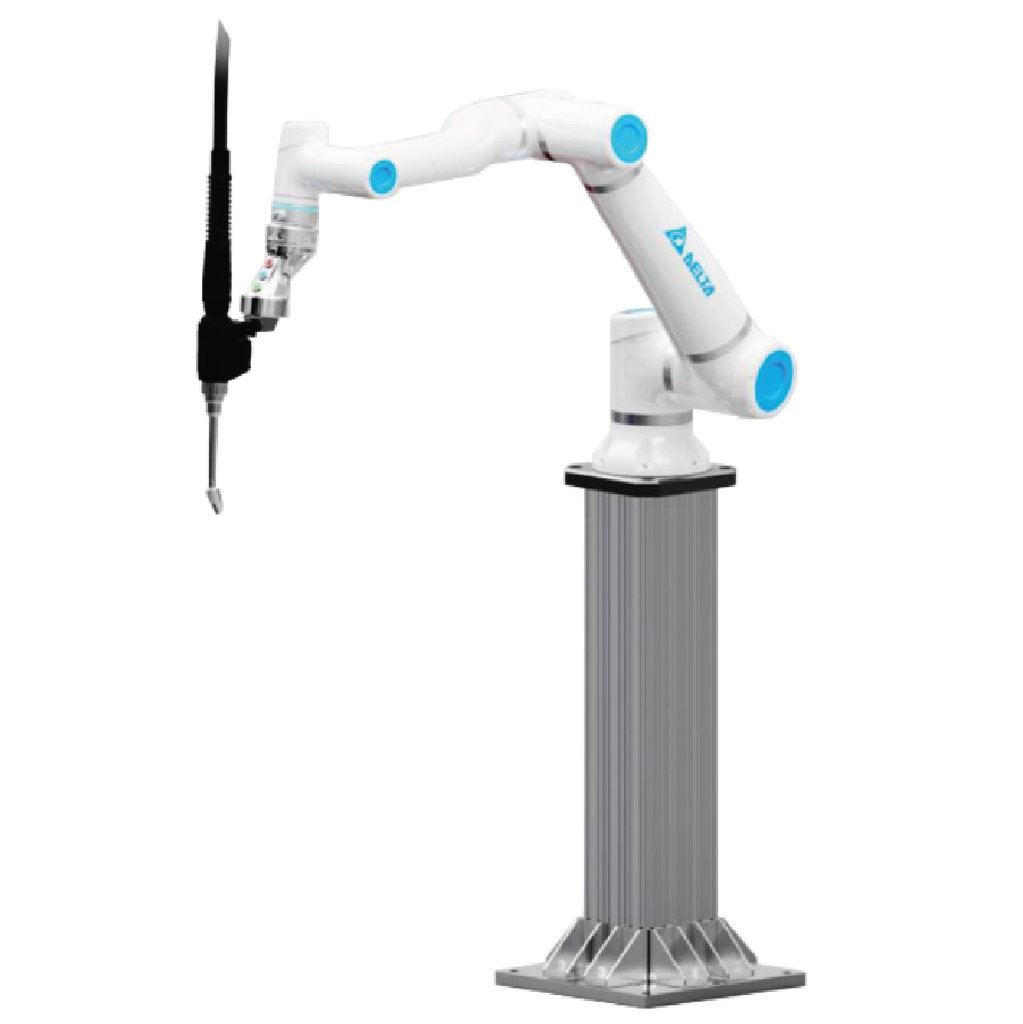

- Welding, grinding, screwing, picking, gluing